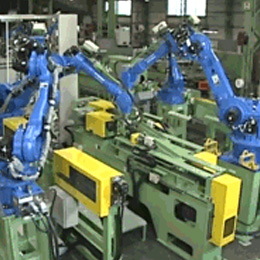

Coil Spring Manufacturing Equipment

Our coil spring manufacturing machines can produce various types of coil springs.

These coil springs are used for automobiles, trains and heavy machines.

We have made the machines for wire diameter up to 100mm.

STEP 4SETTING

Setting Machine

The purpose setting process is to improve fatigue strength of coil springs, and enhance its elastic limit. Setting process can identify "specified load" or "specified height" of coil springs.

Cold Setting UnitB663S

Overview

This is an equipment to make a setting of coil springs after shot peening in a normal temperature two by two. The machine has a function to cool a coil spring, which is peened in a hot condition. Coil Springs after setting are hooked to hanger conveyor for painting. Jigs, which are changed in accordance with shapes, can be automatically changed by jig changer (Option).

Constitution

- Cooling Device by water

- Setting Machine

- Jig Changer (Option)

- Hooking Device (to painting hanger)

- Positioning Device and Transfer Device

Specification

*Table can be scrolled horizontally

| Specification of Product | Bar Diameter | 8~32mm |

|---|---|---|

| Outer Dia. of Coil | 85~200mm | |

| Inner Dia. of Coil (Cylindrical) | 50~160mm | |

| Inner Dia. of Coil (Conical) | Min. 50mm | |

| Free Length (Before Presetting) | 200~600mm | |

| Free Length (After Presetting) | 160~550mm | |

| Direction of Coil | Right | |

| Specification of Machine | Number of Head | 2 heads (System to treat 2 springs every one cycle) |

| Setting Capacity | Max. 3000kgf | |

| Load Detection | Load Cell | |

| Setting Drive | AC Servo Motor | |

| Temperature of Coil Spring | Normal Room Temperature | |

| Measuring Method | Load Measuring Under Specified Height | |

| Cycle Time | 10 sec/cycle(average)(about 600 pcs./Hr) | |

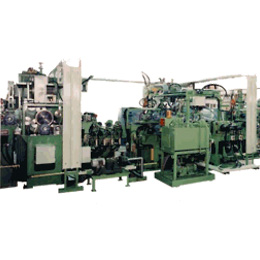

Warm Setting UnitB564W

Overview

This is a equipment to make a hot setting of coil spring, which is extracted from the tempering furnace, two by two. Coil springs after hot setting and cooling by water are transferred to shot peening. Jigs must be changed in accordance with shape of both spring ends and can be changed by automatically by jig changer (Option).

Constitution

- Unloader from Tempering Furnace Conveyor

- Orientation NG Ejecting Conveyor

- Loader to Warm Setting Machine

- Warm Setting Machine

- Unloader to Warm Setting Machine

- Middle Insert Conveyor

Specification

*Table can be scrolled horizontally

| Specification of Product | Bar Diameter | 10~20mm |

|---|---|---|

| Outer Dia. of Coil | 85~190mm | |

| Inner Dia. of Coil | 60~165mm | |

| Free Length (Before Presetting) | 250~600mm | |

| Free Length (After Presetting) | 200~550mm | |

| Weight of Coil Spring | 1.0~8.0kg/pc | |

| Solid Height | over 60mm | |

| Total Turn | Max. 16 | |

| Pitch of Coil | Max. 180mm | |

| Cycle Time | 4.5 sec/pcs.(average) | |