Coil Spring Manufacturing Equipment

Our coil spring manufacturing machines can produce various types of coil springs.

These coil springs are used for automobiles, trains and heavy machines.

We have made the machines for wire diameter up to 100mm.

STEP 1TAPER ROLL

Taper Rolling Machine

This machine performs to roll a heated end of raw material, which shapes coil spring into tapered form.

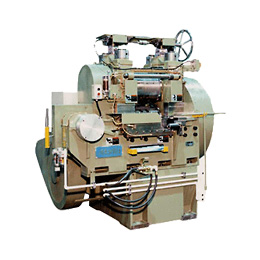

Taper Rolling Machine with Side SettingSHT-125B

Overview

This machine performs to roll a heated end of raw material for coil spring to tapered shape.

A rolling shape can be changed by adjustment of a taper die.

A side pressing device is provided to minimize a spatulation at tapered end and moves synchronously with rotation of rolling roll. Consequently, 2 processes can be performed with good timing.

Constitution

- Taper Rolling Machine

- Side Pressing Device

- Rolling Stopper

- Up/Down Adjustment Device of Upper Roll

Standard : Handle operation method

Option : Motor driving type - Stamping Device (Option)

- Taper Orientation Device of a tail end (Option)

It is possible to automate this machine by installing a loading, unloading device and length positioner.

Specification

*Table can be scrolled horizontally

| Specification of Product | Dia. of Bar | 9~30mm |

|---|---|---|

| Rolling Length | 350mm | |

| Length of Bar | - | |

| Specification of Machine | Rolling Capacity | 125,000kg |

| Revolution of Roll | 45r.p.m | |

| Cycle Time | 14-18sec/end (about 180 end/Hr, Bar dia. 22 mm, rolling length 300 mm) |

|

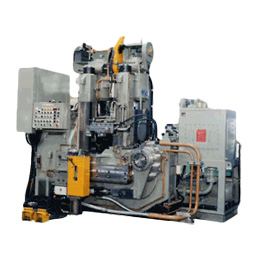

Taper Rolling Machine with Side SettingLT200-600B

Overview

This machine performs to roll an heated end of raw material for a large size coil spring to a tapered shape.

A rolling shape can be changed by adjustment of a taper die.

A side pressing device with hydraulic type is provided to minimize a spatulation at tapered end.

Constitution

- Taper Rolling Machine

- Side Pressing Device

- Rolling Stopper

- Up/Down Adjusting Device of Upper Roll

Standard : Handle operation method

Option : Motor driving type - Material Supporting Roll

- Stamping Device (Option)

Specification

*Table can be scrolled horizontally

| Specification of Product | Dia. of Bar | Max.70mm |

|---|---|---|

| Rolling Length | 600mm | |

| Length of Bar | - | |

| Specification of Machine | Rolling Capacity | 200,000kg |

| Revolution of Roll | 34r.p.m | |

| Cycle Time | 25 - 30sec/end (about 100end/Hr, Bar dia. 40 mm, rolling length 400 mm) |

|

Taper Rolling MachineST100-1000

Overview

This equipment rolls an end of heated coil spring to a tapered shape according to forming data pre-programmed on the PC.

Constitution

- Conveyor for Material Inserting

- CNC Taper Rolling Machine

- Positioning Device for Taper Length

- B side Orientation Machine

- Unloading Conveyor

Specification

*Table can be scrolled horizontally

| Specification of Product | Material Length | 2,250~8,000mm |

|---|---|---|

| Bar Diameter | 19~80mm | |

| Taper Length | 250~800mm |