Leaf Spring Manufacturing Equipment

Since the day of establishment in 1910, Morita & Company has greatly developed with growth of Automobile industry. Our achievement and its originality has been approved as a leading brand for spring manufacturing machines, and M&C brand has gained high trusts internationally.

STEP 2TAPER ROLLING

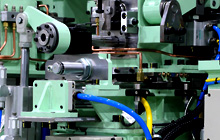

Taper Rolling Machine

The material of leaf spring can be tapered thinly by pressure of taper roll.

CNC Taper Rolling Unit for Leaf SpringLTP202R

Overview

This machine performs to roll a heated end of raw material of leaf spring to a tapered shape. Taper rolling is done by upper and lower working roll(round shape) and a draw bench. Any shape of taper can be formed by CNC control of up/down movement(Electric Servo System) of an upper roll. Consequently, this machine is most suitable for parabolic taper rolling. This machine has a capacity to store a shape data of many types of products.

Constitution

- Parabolic Taper Rolling Machine

- Loading Device

- Draw Bench and Extracting Device

- Roll Assembly Exchanging Device

- Material Supplying Device (Option)

- De-scaler (Option)

- Transfer Device for Next Process (Option)

Specification

*Table can be scrolled horizontally

| Specification of Product | Leaf Width | 44.5~125mm |

|---|---|---|

| Leaf Thickness | Max. 50mm | |

| Material Length before Rolling | 800~2000mm | |

| Length after Rolling | 1000~2500mm | |

| Tapered Length | Max. 1500mm | |

| Numbers of Pass | Max. 10 passes | |

| Specification of Machine | Rolling Capacity | 60,000kg |

| Up/Down of working roll | AC Servo Motor Drive | |

| Rotation of working roll | Variable Speed Motor Drive | |

| Draw Bench | AC Servo Motor Drive | |

| Clamp of Draw Bench | Hydraulic Drive | |

| Transportation and Positioning | Motor & Pneumatic Drive | |

| Cycle Time | Taper length 800 - 1,000 mm: (7.2-8.0 sec) x pass no. + 7.5 sec Taper length 300 - 500 mm: (5.7-6.5 sec) x pass no. + 7.0 sec |

|

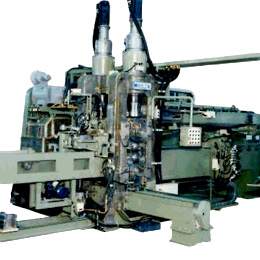

Fork Arm Rolling MachineLTP405

Overview

This is rolling machine to roll the leaf thickness and width of heated fork arm material. The width is rolled by squeezing roll, and the leaf thickness is rolled by working Roll & Draw bench. The tapered shape can be formed by NC for up/down movement of upper roll (Electric servo system) without changing forming dies. This machine has a function to storage the product shape data of a various kind.

Constitution

- Squeezing Device

- Squeezing Roll Changer

- Insertion Device

- Fork Arm Rolling Device

- Draw Bench & Ejecting Device

- Roll Ass'y Changer

- Material Feeding Device

- Descaler

- Product Number Marking Device

- Conveyor for Next Process

Specification

*Table can be scrolled horizontally

| Specification of Product | Leaf Width | 70~90mm |

|---|---|---|

| Leaf Thickness | 34~106mm | |

| Material Length before Rolling | 900~2200mm | |

| Number of Pass | Max. 15 passes | |

| Specification of Machine | Rolling Power | 250,000kg |

| Up/Down Working Roll | AC Servo Motor Drive | |

| Working Roll | Rotational Variable Speed control Motor Drive | |

| Draw Bench Drive | AC Servo Motor Drive | |

| Draw Bench Clamp | Hydraulic Drive | |

| Conveyor/Positioning | Motor & Pneumatic Drive |